Sugar Railcar Unload & Process Facility

CLIENT: Sweetener and Beverage Producer

PROJECT: Sugar Railcar Unload & Process Facility

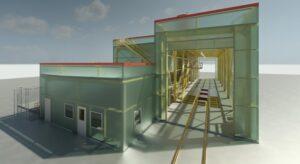

BACKGROUND: The client was looking to install a new facility to unload railcars and store and process sugar. The facility has approximately 10,000 sq feet of floor space, including offices, processing facility, and railcar unload bay. There is also a 17 ft. deep x 1200 sq ft. basement in the railcar unload bay.

CHALLENGES:

Meeting a demanding project schedule was the top metric for success for our client.

This meant that several design disciplines needed to work simultaneously. ADF was able to create an advanced 3D model of the structure to help coordinate our structural design to adapt with constantly evolving architectural, process, and HVAC designs by other firms. Our shared model was used to quickly modify designs to work together without a lengthy back-and-forth period.

WORK COMPLETED:

ADF completed the following:

- Develop the structural specifications and design drawings for the following items:

-

- New building foundations including basement with 2’-6” thick walls and 3’-0” thick floor slab supporting railcars, hoppers, and sugar conveying equipment. New adjacent mat foundation supporting 3 silos 14’-0” diameter x 76’-10” high.

- New concrete floor slab for offices, process area supporting equipment and mezzanine level, and railcar unloading bay supporting railroad tracks.

- New structural steel framing spanning to basement walls supporting railcars, and sugar unloading equipment.

- A steel mezzanine level in basement, platforms to access the tops of railcars with fall protection system, and stairs with landings to access all roof levels.

- Structural steel framing for a 30’-0” high train bay and process area, and a 16’-0” high office area.

- Construction Phase Scope:

-

- Structural shop drawing review.

- Answered RFIs and other construction-related questions related to ADF design documents as needed.

SUMMARY:

The use of progressive 3D models allowed collaboration between all engineering disciplines, project stakeholders, vendors, and contractors. It allowed us to overcome multiple challenges and resulted in successful project completion on budget and schedule.

During this project we learned several new approaches to structural design as well as methods to improve multi-discipline coordination that can be applied to other projects in different industries using bulk unloading and storage.

For additional information on Structural design for plant extraction, please contact wlawler@adfengineering.com or go to https://adfengineering.com/contact-us/ .