Existing Plant Packing and Building Extension

CLIENT: Food and Industrial Ingredient Producer

PROJECT: Existing Plant Packing Building Extension

BACKGROUND: The client selected ADF Engineering to increase capacity for their packing process.

CHALLENGES:

- Tight space

A new building had to be designed and built adjacent to the existing structure with a limited footprint to avoid interferences with existing structures and truck access. The equipment arrangement required the design of a tower with three mezzanine levels. - Limited existing drawings

Limited structural drawings were available regarding the existing warehouse pile caps which required exploratory digging and impacted foundation design. - Accessibility

The new building was designed to match the existing warehouse ground floor which was 4’ – 0” above grade and required an elevated slab supported on compacted fill. Equipment mezzanine levels were designed to match the existing manufacturing building floor elevations and incorporate the existing stair for access with an additional stair designed to access to the lowest level.

WORK COMPLETED:

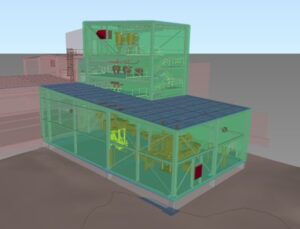

ADF performed multi-discipline engineering services and completed preliminary and detail design, bid packages, and construction phase assistance. This project layout was ultimately designed to benefit plant operation and maintenance. It was comprised of modification to the existing extraction building and designing a new building extension in an unoccupied space.

Structural design of this new arrangement included:

- Laser scanning of the area to collect locations of all existing structures. These scans were used in conjunction with any available drawings to create a 3D model.

- Develop the structural specifications and design drawings for the following items:

- Building foundation including driven concrete-filled piles with pile caps and grade beams

- 1’ – 0” concrete floor slab supported compacted fill within 1’ – 4” thick retaining walls

- New structural steel framing for building and three-story tower to provide access to all equipment associated with the new open-mouth packing line. The tower also provides maintenance access to the existing manufacturing building.

- Modifications to existing steel to access new building tower equipment mezzanines.

- Modifications to existing warehouse and manufacturing building to remove wall sections for access to the new building extension.

- Design of a monorail for future equipment maintenance

Construction phase assistance including:

- Pre-construction meetings with client and contractor

- Structural shop drawing review

- Respond to RFIs and other construction related questions

Process & Mechanical & Piping design of the extraction expansion included:

- Point cloud modeling

- 3D equipment layouts

- Equipment reviews

SUMMARY:

The use of progressive 3D models allowed collaboration between all engineering disciplines, project stakeholders, and contractors, overcoming multiple challenges and resulted in successful project completion on budget and schedule.

For additional information on Structural design for plant, please contact mcorsi@adfengineering.com or go to https://adfengineering.com/contact-us/ .